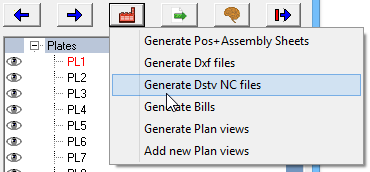

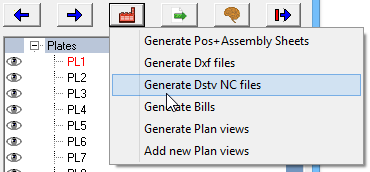

You can start this function by clicking the button  in sheets manager

in sheets manager  .

.

Dstv files can be read by most cutting- and drilling CNC machines.

Also some plate machines (laser, plasma) can read Dstv files.

The Dstv files will be stored in the same folder as the location of the 3D dwg file.

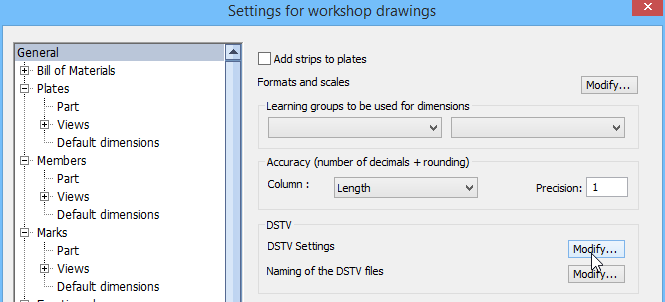

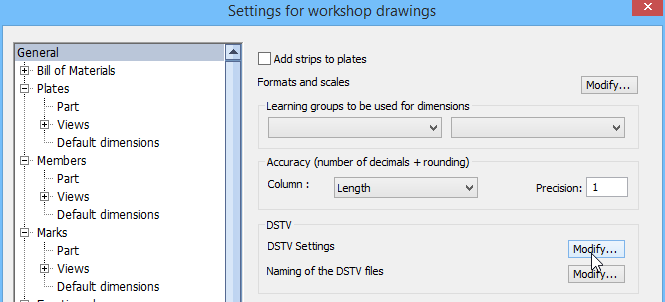

To change the settings of the Dstv files, you need to click the button  in sheets manager

in sheets manager  .

.

In the list you need to click on General, so that in the middle of the dialog box you can click on the button  next to DSTV Settings.

next to DSTV Settings.

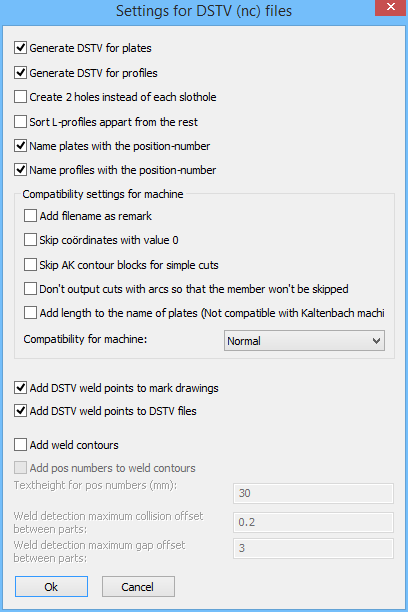

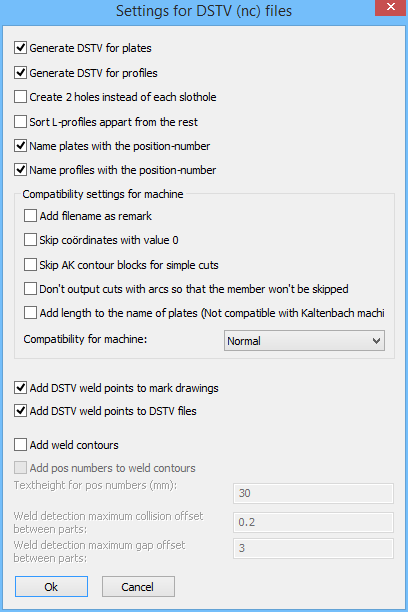

This dialog box has the following options :

- Create 2 holes instead of each slothole. If activated then Parabuild will insert two holes in the Dstv file instead of a single slothole. This is useful if the machine doesn't have a tool for creating slotholes.

- Sort L-profiles apart from the rest. If activated then the dstv files of L-profiles will be stored into a separate folder. This is useful when the L-profiles need to be done with a different machine.

- Annotate plates with the position number. The machine that supports this will engrave/write the position number on the plate.

- Annotate profiles with the position number. The machine that supports this will engrave/write the position number on the profile.

- Compatibility settings for machine. Some machines do not follow the Dstv standard, or are based on an old version of the Dstv standard. That is why some compatibility settings are necessary in order to support as many machines as possible. Only change these settings if you are experiencing problems with reading the dstv files in your CNC machine.

- Add filename as remark. Some machines expect this, and it does no harm.

- Skip coordinates with value 0. Some machines do not expect any values with value 0 while this shouldn't make a difference.

- Skip AK contour blocks for simple cuts. Some machines always need the AK block, others don't support the AK block at all.

- Don't output the cuts with arcs so that the member won't be skipped. Parabuild skips the profiles that contain curved cuts. If you activate this setting then these profiles will not be skipped any more but the curved cuts inside the profiles will be skipped.

- Add length to the name of plates. Normally the plates receive a name such as PL150x10. But some machines also expect the length in this name, so it will become PL150x10*200.

- Compatibility for machine. These are a collection of changes to the standard that some old machines need.

- Add DSTV weld points to assembly drawings. For each weld point in Dstv Parabuild well draw a cross in the assembly drawing.

- Add DSTV weld points to DSTV file. The drill of the machine can be used to create a dot to facilitate the welder. You can find out more about weld points here.

- Add weld contours. The circumference of the touching face of the main part and the welded part will be engraved/written by the machine.

- Add pos numbers to weld contours. The position number of the welded part will also be engraved close to the contour.

- Text height for pos numbers (mm).

- Weld detection maximum collision offset between parts. If the welded parts collide with each other too much then the weld contour won't be added to the dstv file.

- Weld detection maximum gap offset between parts. If the gap between the welded parts is too much then the weld contour won't be added to the dstv file.

in sheets manager

in sheets manager  .

.

in sheets manager

in sheets manager  .

. next to DSTV Settings.

next to DSTV Settings.